Low mobility (compaction) grouting involves the injection of a low-slump mortar grout to densify loose, granular soils and stabilize subsurface voids or sinkholes.

Common uses

Process

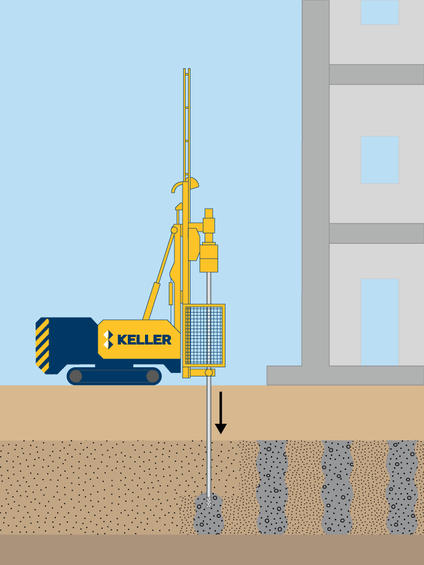

Low mobility grouting densifies loose granular soils (compaction grouting), reinforces fine-grained soils, and stabilizes subsurface voids or sinkholes by the staged injection of low-slump, low mobility aggregate grout. An injection pipe is typically inserted to the maximum treatment depth when performing soil improvement. The grout is injected as the pipe is slowly removed in lifts, creating a column of overlapping grout bulbs. The expansion of the low mobility grout bulbs displaces surrounding soils. Compaction grouting increases the density, friction angle, and stiffness of surrounding granular soils. The effectiveness of the improvement can be increased by sequencing the low mobility (compaction) grouting work from primary to secondary to tertiary locations. In all soils, the high modulus grout column reinforces the treatment zone.

Compaction grouting was developed in the 1950s as a remedial measure for the correction of building settlements. Over the past 25 years, low mobility grouting technology has evolved to treat a wide range of subsurface conditions for new and corrective construction. These include rubble fills, poorly placed fills, loosened or collapsible soils, karst conditions, and liquefiable soils.

Low mobility grouting often offers an economic advantage over conventional approaches such as removal and replacement or piling and can be accomplished where access is difficult, and space is limited. Low mobility grouting for treatment beneath existing structures is often selected because the low mobility grout columns do not require structural connection to the foundations.

Advantages

Quality assurance

Keller's quality control includes procedural inspection and documentation of the work activity, testing to ensure proper mix design and injection rates, and verification of ground improvement where applicable. Ground improvement can be assessed by Standard Penetration Testing, Cone Penetrometer Testing, or other similar methods. Data recording of important grouting parameters has been utilized on sensitive projects.